At this very hour, while Intel in general, and Intel Israel in particular, with great patriotic excitement, are preparing for yet another official announcement of a new generation of Core processors, the 13th in number for those who are counting, in certain rooms in the company’s development center in Haifa, many engineers are busy, planning and designers in the first steps, and even more, of the next generation of Core processors, and probably also on the one after that.

asItzik Silaiscorporate vice president at Intel worldwide, who is responsible for the integration of Intel’s products in desktop and mobile computers, said at the beginning of TechTour.IL – the first time that Intel chooses to announce a new generation of processors in Israel, with a very handsome delegation of dozens of journalists from around the world – takes about 30 months from now who start working on a processor and until the first unit ready for shipment leaves the production line.

In this long framework of months, and actually years, there are several very fundamental stages in the route that each processor goes through, even in the case of Raptor Lake, until it reaches the customer – including several round trips, if necessary, between the factory and the development center because in it, in other rooms and places Others in the cluster of buildings that make it up, many laboratories are located whose purpose is to physically test the processors to make sure that they will actually reach the customer in the end when they perform what they are supposed to perform.

Validation – search and sift the bugs

Validation, as you can understand from the name of the function of this huge laboratory, is to provide confirmation, even though what they are doing works, you could say, it is the opposite: the people of this laboratory can be said graphically, ‘attacking’ the processors that come after initial production with all the tools at their disposal To prove that they meet all the performances defined for them during the design phase of the processors – they are tested against the various operating software, including some that the 200 validation staff write themselves, they are tested to show that they are protected against malware, to examine the energy consumption and many other variables.

Scattered throughout this lab are hundreds, if not thousands, of computers or actually motherboards to which external devices are connected, and in each of them a test software is run again and again and again to check that there are no bugs in the processor. These motherboards are produced by the lab’s own people, and in the end, if everything is fine, they even serve as a reference for motherboard and PC manufacturers.

One of the most important moments is the stage where we check whether the processor is able to perform the initialization process for the traditional operating systems, mainly Windows, to see if it is functioning properly. In Alder Lake it happened from a distance, this time it happened traditionally, and when it happens, it’s one of the most formative moments there is, even for the employees.

This stage allows, in another part of this laboratory, to test the processors in different applications according to working conditions such as games for example, and here and there there are also ‘enemy’ systems against which the performance is compared. In this place they also check, for example, whether the processor, for example, provides all the power in every situation or whether the voltages are different, there is leakage that harms the performance, etc. – between the motherboards it is not surprising to find different scopes that measure, for example, the waveform, the voltages, the loads and more.

In another room you also find computers from different manufacturers. They receive the first processors at a relatively early stage to build systems based on them, and as part of the work with Intel they send certain models to check that everything works as it should.

The important classification

The classification laboratory, Class Lab, is also a huge and very noisy room where you find dozens of machines that work non-stop in order to check whether they fit their classifications. The laboratory itself does not determine the types of processors themselves, but the data it provides determines, for example, whether processors should be of the Core i9 or Core i3 type and any other processor in each generation.

This laboratory is already testing the production line, and almost every processor, and even all of them, go through here to see that they are simply normal, exactly according to the initial design, in the range of temperatures and working conditions, with a large part of all the tests being developed in the laboratory itself.

Another interesting lab is the I/O processor. This is one of the interesting points in the tour because these tests are actually performed by robots for all intents and purposes. In this laboratory, the behavior of the input and output ports of the processors is examined, and this is done in front of a large variety of board configurations, with such and such memories, and anything else that the processor communicates with directly on the motherboard.

Next to each machine more or less, and there are several machines with different levels of work speed and function, stands a pile of processors in long rows inside a kind of drawer. The robot approaches, sticks a mast processor with a special magnet to the end of a transmission leg, and embeds it in the motherboard it is working with. Immediately after that, the cooling system is also attached, and the test starts – and so it happens again and again.

Bugs Bugs Chase

What is the chance of software, a game for that matter, reaching the market in the current era without any glitches, so that it will run exactly as the developer planned without any glitches? A processor, in the end, even though it is something physical, is actually based on a lot of planning and software, and even in its case there can be faults, bugs – and this is part of the main reason that almost every processor at Intel works a very heavy journey, so that it finally reaches the customer free of faults – at least in the hope that it will actually happen.

And when you find bugs there is of course a unit, or a laboratory, whose job it is to filter it out, and not surprisingly it is called the Debug Laboratory and there you find one of the oldest workers, Anne, who is not the oldest, Eric Shemerwho has already been working at Intel Haifa for 40 years, and at the beginning of the journey between the laboratories also provided history lessons regarding the establishment of Intel Israel in 1974 and its first developments – and the fact that he also came to Intel somewhat by mistake.

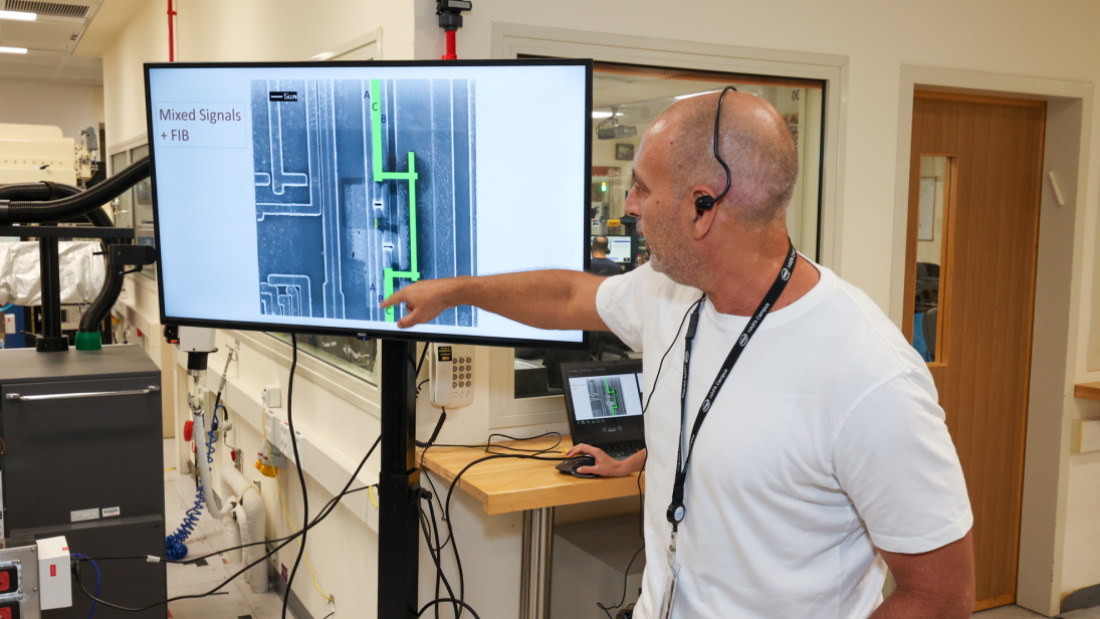

We already know that there is a problem with this processor, but the in-depth analysis is done here, and we will just remind you that it is an entry into the depths of the processor to work at nano sizes to find the source of the problem. One of them, the one shown in the picture above, could be, for example, that one of the actual wirings is not manufactured correctly. Not only do you need to identify this problem, you also need to offer a solution, and in this case, for example, it involves cutting and creating a bypass that will provide an answer to the problem.

Another problem could be that one of the components does not receive enough voltage so that the speed it outputs does not meet the standard, and in this case too a test is performed, using a laser system, to locate exactly the component causing the problem and to provide some kind of solution.

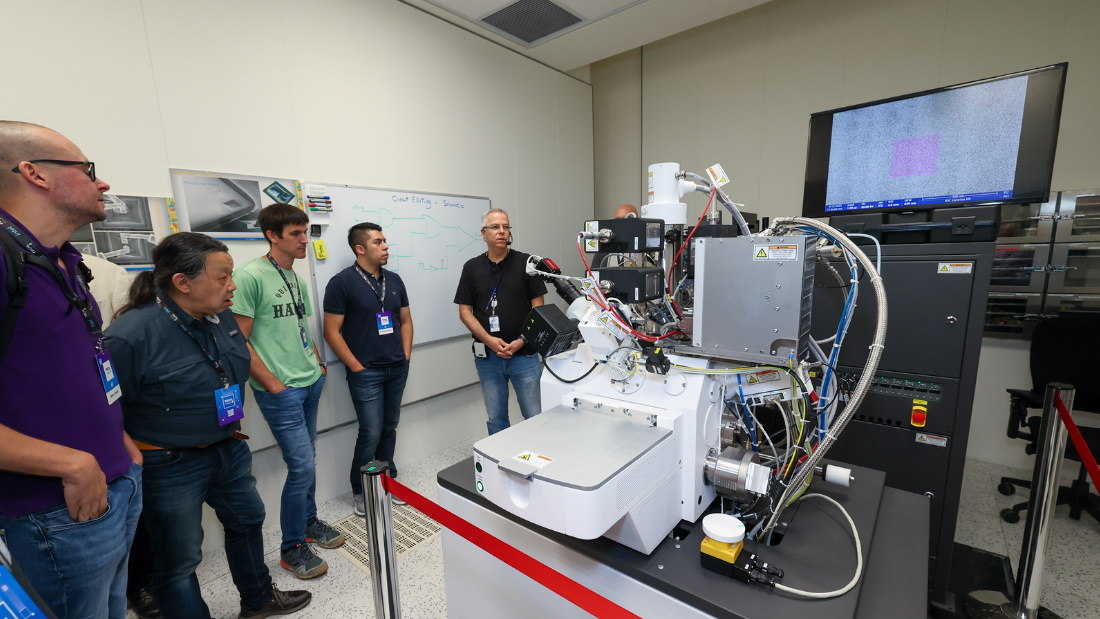

So do you run to the factory and start producing again? Not yet, first of all you have to get to the operating room, the more accurate name of which is the analytical laboratory. In this laboratory, whose system sits on precise balances to ensure that at any given second everything is properly aligned for work, the proposed repair is actually carried out, on the processor itself, on the unit that came from the factory and where the fault was found.

The engineers operating this machine penetrate the processor from below, below the silicon itself, open a passage to the point where the repair needs to be made, and do it according to the instructions. Again, one can think of a type of very delicate analysis that must be very precise, and considering the hundreds of millions of transistors that are in each processor, it’s almost a wonderful world, prying inside like this to get to exactly the tiny point that needs to be fixed.

Even after that, the processor with the repair is not activated with a quick conversation with the factory in Kiryat Gat. Before that, it goes through the strict tests again to make sure that the repair did eliminate the bug(s), and only after that it returns to the factory for another round of production.

not short

If you go back for a moment to the slide at the beginning of the article, and look at it again perhaps more carefully, you will see that all these processes of testing and production and again testing and more production until a decision is made that these are the processors that go to the market definitively, lasts only about a dozen months, about a third of the entire process that includes the The planning and design stages of the new processor stack.

Intel, and probably every chip and processor manufacturer, invests a lot in the validation and classification of the processors to ensure that there are no faults in them, if at all, and this exposure of what happens behind the scenes reveals the large investment on the one hand and also how not very easy it is to produce a processor.