Even pampered, the battery of smartphones degrades inexorably: we feel the need to change it every three or four years. The maneuver only required a minute a decade ago: to access it, it was often enough to remove a plastic cover a bit recalcitrant. Today, the operation easily takes thirty minutes and requires so much skill that many do-it-yourselfers give up along the way. Is this increase in complexity justified?

Three main difficulties stand in the way of a handyman wishing to change the battery of a mobile, its screen, or any other fragile part. The first is of a sticky and tenacious nature: it is the glue that firmly holds the screen of the mobile in place, as well as its back. To soften this glue, it is necessary to use a heater, and to detach the elements, a suction cup. The maneuver is so delicate that repair professionals sometimes break the back of mobiles separating it from the rest.

Is this glue, which complicates repairs so much, irreplaceable? Modern smartphones are increasingly waterproof, unlike their ancestors, and this material is an excellent barrier to infiltration: “It is light, economical, durable and easy to remove”, admits Maarten Depypere, head of repair policy at iFixit, a repair manual site. As a bonus, she “reinforces the rigidity of the smartphone and protects its electronic components”boasts a spokesperson for the manufacturer Oppo.

Replace glue

However, a few rare manufacturers are exploring alternative solutions. Fairphone, a Dutch manufacturer of smartphones that are particularly easy to repair, replaces the glue with screws. Crosscall, a French manufacturer of shockproof mobiles, mixes screws and glue in reduced quantities. Their smartphones are easier to disassemble, of course, but they also turn out to be heavier and bulkier. “We had to add a gasket that slightly thickens the mobile”admits Nicolas Leclerc, research and development manager at Crosscall, adding that “the threads widen its perimeter”.

For Miquel Ballester, director of product management at Fairphone, it’s all about priorities. “The design of a smartphone is extremely complex, we have to choose our battles. If a manufacturer wants to offer the cheapest product, they won’t care how their smartphones disassemble. This is the case for several brands. »

A complex tangle

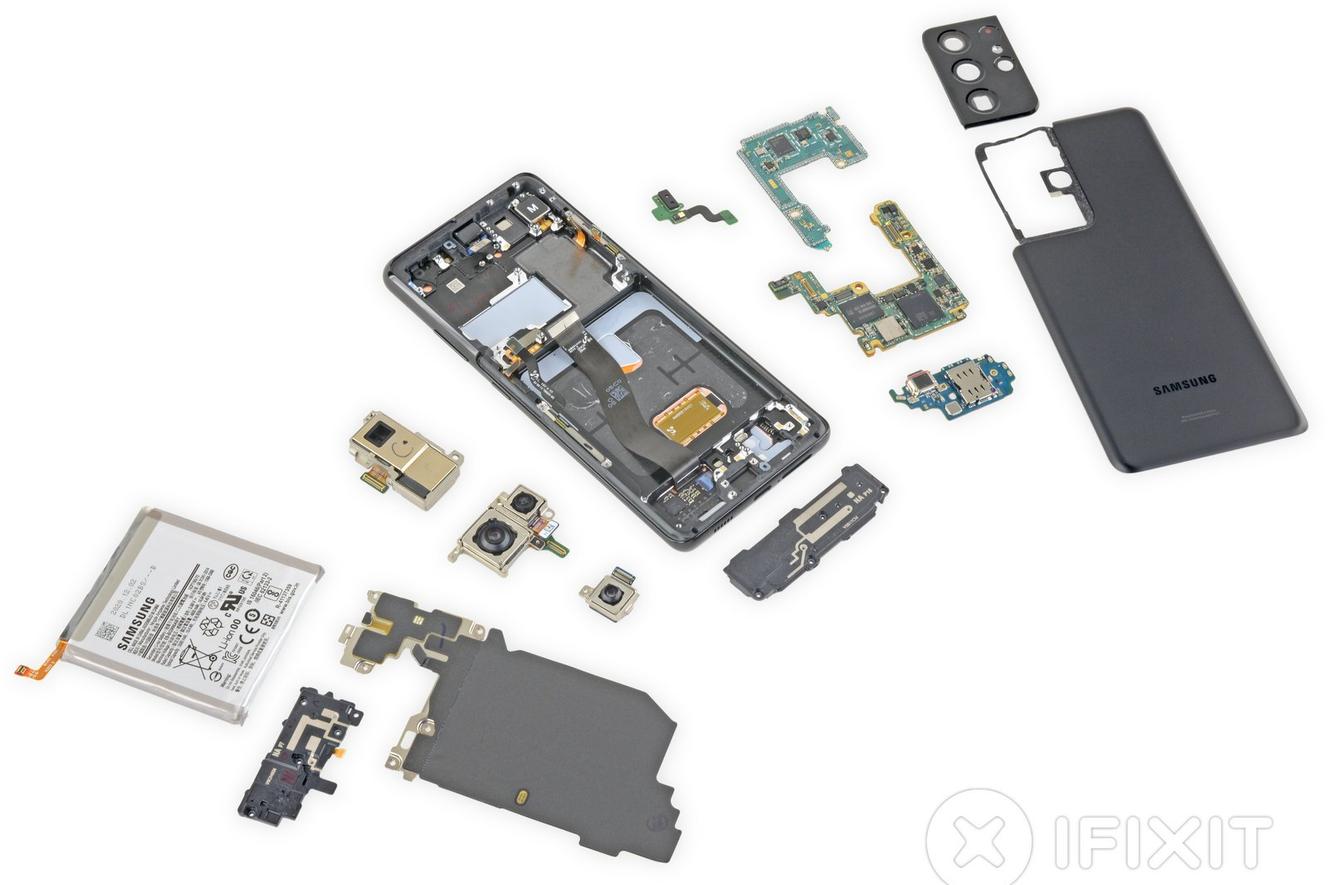

The second obstacle encountered by DIY enthusiasts is the tangle of parts. It is common to disassemble several elements before being able to release the battery. To remove the screen of an Android smartphone, it’s even worse: you have to remove its back cover then detach a lot of parts, which requires a lot of skill, a certain amount of self-confidence, and when the time comes to put everything back together, an excellent memory.

It would be easier to be able to disassemble the two sides of a smartphone to access, as desired, its screen or its back. This is precisely the design to which Apple returned with the iPhone 14 Pro, after five years of imposing a disassembly from the front, making the rear very difficult to replace. “That’s what we do too.testifies Nicolas Leclerc of Crosscall, mBut that complicates the design. Passing the antenna around the mobile becomes difficult, as does inserting the buttons. » In addition, the smartphone, here too, thickens.

The iPhone 14 Pro may be accessible from both sides, but almost all of its parts continue to pile up in its back in an intimidating way, complicating many repairs. “We could find creative solutions to this problem”, testifies Nicolas Leclerc. For example, divide the pieces into two layers, one accessible from the front, the other from the back.

Tiny cables

There remains a third difficulty that can prevent an individual from repairing his smartphone himself: the size of the cables. The most devious are ultra-flat, a good millimeter wide and plug into microscopic sockets. Their handling requires good eyes and a hand that does not tremble. But here too there are alternatives. At Crosscall, some components plug directly into the circuit boards, like small Lego pieces. At Fairphone, the main cables have their own connector, large enough to be clipped easily by the majority of individuals.

This solution does not appeal to Oppo, a large manufacturer who fears that the proliferation of connectors “increases failure rates”. Asked by The worlda spokesperson for the Chinese brand explains that “reliability must trump repairability”. But Crosscall and Fairphone rather insist on two other disadvantages for those who seek to simplify these connections: the manufacture of the mobile becomes more complicated and, once again, the smartphone becomes thicker.

The appetite of the general public

It’s a compromise that keeps coming back: a mobile more “removable” is a bulkier mobile, which should not be overlooked according to Régis Koenig, Director of Services and Sustainability at Fnac Darty: “The smartphone is the tool we use most often during the day. It must be thin, light, practical. »

However, we will be reassured by observing the most removable of current smartphones, the Fairphone 4, which is only a few millimeters thicker than a conventional mobile, and weighs only a few additional tens of grams. “We are a small company of one hundred and thirty employeesemphasizes Miquel Ballester. Imagine what big manufacturers could do if they followed this idea. They would probably find much more compact and ingenious solutions. »

If Apple, Samsung or Oppo marketed a larger smartphone that was easier to disassemble, it would no doubt appeal to some consumers put off by the austerity of the Fairphone. Oppo’s spokesperson believes that however “it would be a niche market”. “Dismantling” is a hidden quality, which is less appealing than the finesse of a mobile, synonymous with elegance. An argument that annoys Miquel Ballester: “The marketing departments of large manufacturers are good at making things visible that they want to highlight. » For Nicolas Leclerc, “It’s a bit in tune with the times and it would be good to come there”.

Even if Apple, Samsung and other major manufacturers start to compete with Fairphone on the field of disassembly, many consumers will continue to remain oblivious to the problem of repairability, even if a third of their smartphones break when observed on a period of three years, according to a study by the manufacturer of rugged mobiles Bullitt.

Legislation could, however, bring the entire market back to this concern soon. The European Commission is working on a text that would oblige manufacturers to make their batteries replaceable by a layman, without specific tools – except in the case where this battery is particularly durable and weakens shortly after a thousand charge cycles. “Goodbye glueenthuses Maarten Depypere of iFixit. We are hopeful that this legislation will pass in 2023.”