2025-03-18 00:28:00

Table of Contents

- The Future of Audi: Navigating Job Cuts and the Electric Vehicle Revolution

- Understanding the Job Cuts: A Necessary Sacrifice?

- Transitioning to Electric: Audi’s Long-Term Vision

- Pressure from Global Competitors

- The American Context: A Broader Reflection

- Union Perspectives: Navigating Complex Waters

- Experts Weigh In: Insights from Industry Leaders

- Long-Term Implications for the Industry

- Frequently Asked Questions (FAQ)

- Audi’s Electric Vehicle Revolution: An Expert’s Take on Job Cuts and the Future of Automotive

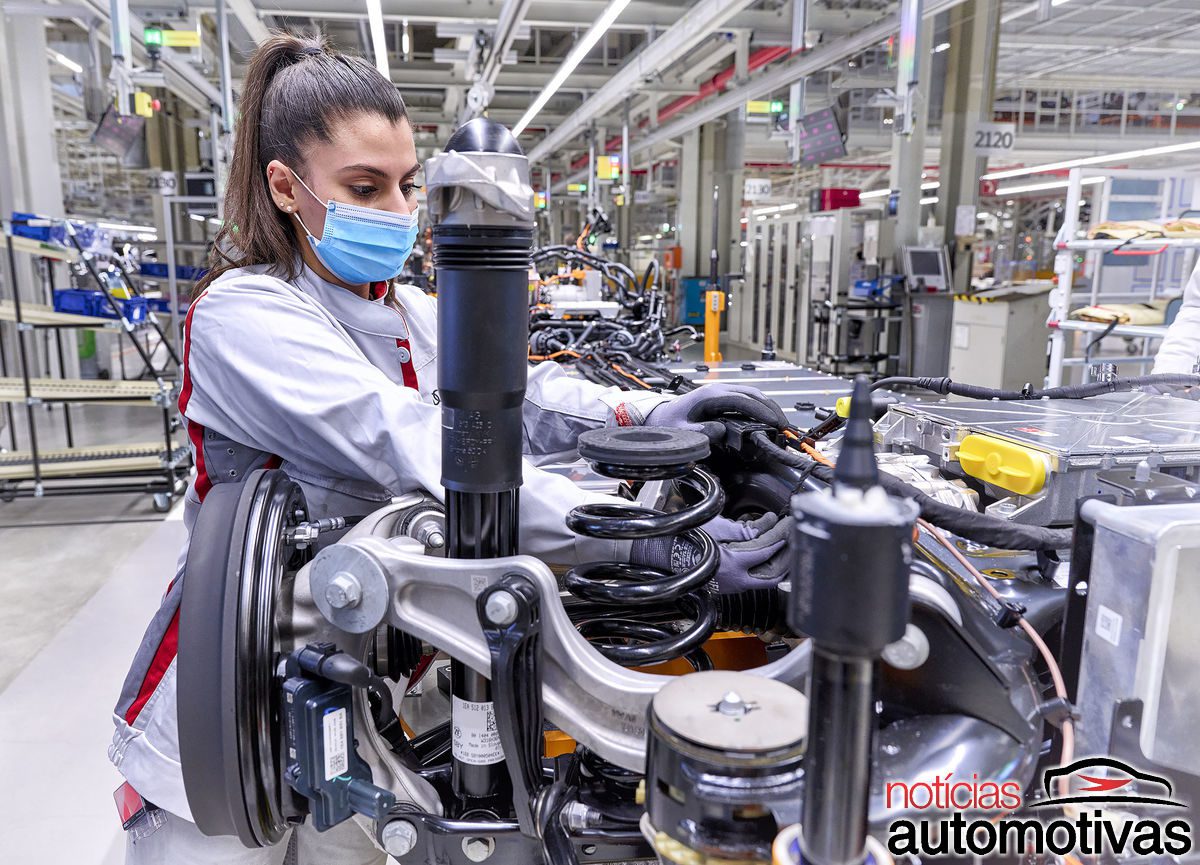

In an era where innovation competes directly with tradition, Audi stands at a crossroads, grappling with the immense pressures of the electric vehicle (EV) market and economic volatility. With a recent announcement of potential job cuts affecting up to 7,500 employees in Germany by 2029, the prestigious automaker is poised to make significant strategic changes as it transitions towards a more sustainable future.

Understanding the Job Cuts: A Necessary Sacrifice?

The decision to cut jobs has sparked considerable debate. Audi’s management, in collaboration with employee representatives, has framed these layoffs as essential for streamlining operations and enhancing efficiency amidst a highly competitive landscape. By cutting a maximum of 7,500 positions, Audi aims to save approximately €1 billion annually, which is critical as it allocates €8 billion towards investments in its German facilities over the next four years.

But what does this mean for the automotive landscape? With nearly 48,000 job cuts slated across the Volkswagen Group—including significant reductions at Porsche and the Cariad software unit—this wave of layoffs emphasizes the urgent need for the German automotive industry to adapt to new realities.

Impact on the Workforce

Such drastic measures may be seen as a necessary evil, yet they raise significant concerns about job security in a sector that has historically prided itself on stability and employment opportunities. Unions express worry over the shift in production of EVs to countries where labor costs are lower, which further underscores the seismic shifts occurring in the automotive industry.

Transitioning to Electric: Audi’s Long-Term Vision

Since 2019, Audi has laid off around 9,500 production workers as part of a strategic initiative to finance its transition to electric vehicles. The objective is clear: to boost profit margins, increasing them from 9% to 11%. However, hurdles remain. The operating margin fell to 4.5% in the first three quarters of 2024, down from 7% in 2023, due to stagnant sales and closures like that of the Brussels facility.

This situation challenges the notion of progress and raises an intimidating question: Can Audi, and the automotive industry at large, pivot effectively towards a sustainable future without sacrificing its workforce?

The Ingolstadt Initiative: New Developments

Despite these challenges, Audi is determined to innovate. Plans to produce a new electric entry model at its Ingolstadt factory reveal a commitment to reassembly amidst disruption. This model is expected to align with consumer trends favoring EVs, marking a significant shift in the company’s product lineup aimed at regaining traction in the market.

Pressure from Global Competitors

As competition intensifies, Audi, along with other German manufacturers, faces pressures not only from established rivals but also from emerging players in the EV sector, particularly from companies in Asia and the United States. This dynamic landscape lends urgency to Audi’s efforts, with strategic partnerships and technology sharing emerging as potential pathways to success.

The Role of New Technologies

Audiences are watching to see how Audi will leverage technology. For instance, the rise of artificial intelligence and advanced manufacturing processes could play pivotal roles in enhancing operational efficacy and fostering a sustainable production paradigm. Companies such as Tesla have showcased the competitive edge that cutting-edge technology can yield, raising the stakes for traditional manufacturers such as Audi.

The American Context: A Broader Reflection

In the United States, the automotive industry is similarly facing a paradigm shift. Recent legislative moves aiming to bolster EV production have disrupted traditional manufacturing shapes, as American consumers become increasingly invested in sustainability. This shift highlights the interconnectedness of global automotive strategies, where decisions made in Germany resonate strongly with the American market.

Challenges within the U.S. Market

American automakers have also instituted layoffs and restructurings to realign their focus on electric vehicles, mirroring Audi’s strategies. Ford, General Motors, and Stellantis have announced substantial workforce reductions, highlighting the broader uncertainty paradoxically intertwined with the march toward a greener future.

In light of these challenges, labor unions have been vocal about their concerns. Joerg Schlagbauer, head of the workers’ council at Audi, noted the difficulties surrounding these negotiations, emphasizing that tough decisions were made in search of pragmatic solutions. The need for collaboration across unions, corporate management, and government stakeholders has never been more paramount.

Ensuring Worker Safety: An Unprecedented Commitment

Audi has, however, offered some reassurance by extending employment security guarantees for its German units until 2033. This commitment aims to quell union fears about job security as the industry transforms. The balance between innovation and the protection of workers’ rights will be critical to maintaining morale during these transitional phases.

Experts Weigh In: Insights from Industry Leaders

Paul E. Avery, an auto industry expert with over three decades of experience, shares his perspective:

“The shift toward electric vehicles is not just a trend; it’s an inevitability. However, the pace at which companies like Audi can adapt will determine their survival. Cutting jobs is a painful but often necessary path, not just for the company, but for the health of the industry as a whole.”

Exploring Workforce Re-training Programs

In tackling this balancing act, Audi and other automotive manufacturers must consider investing in reskilling initiatives to prepare their workforce for the technological advancements on the horizon. Emphasis on training programs to help laid-off workers transition into roles that the EV sector demands could mitigate the adverse impacts of job cuts.

Long-Term Implications for the Industry

The road ahead for Audi and the broader automotive industry remains fraught with uncertainty and opportunity. The challenge extends beyond immediate job numbers, calling for a strategic vision that reconciles innovative practices with socio-economic responsibilities. How will Audi’s workforce evolve, and what lessons will the industry learn as it responds to a rapidly changing economic environment?

Conclusion: Shaping Our Electric Future

As Audi navigates these turbulent waters, the future will ultimately depend on the company’s ability to balance technological advancement with the welfare of its workforce. The electric vehicle revolution may be a transformative landscape, but it also calls for an inclusive approach that ensures no worker is left behind.

Frequently Asked Questions (FAQ)

What are the reasons behind Audi’s decision to cut jobs?

Audi’s decision stems from the need to reduce costs and increase operational efficiency as it invests heavily in transitioning to electric vehicles.

How many jobs are being cut in total across Volkswagen Group?

Volkswagen Group’s total cuts are around 48,000, including those from Audi, Porsche, and other units.

What measures is Audi taking to secure employee welfare amidst layoffs?

Audi has extended job security guarantees for its German units until 2033, aiming to alleviate concerns about employment stability.

How will Audi transition towards electric vehicles?

Audi intends to invest significantly in its facilities and aims to introduce several new electric models aimed at capturing a larger share of the EV market.

In conclusion, although the winds of change may be unsettling, they promise to usher in a future that harmonizes automotive innovation with responsible labor practices.

Audi’s Electric Vehicle Revolution: An Expert’s Take on Job Cuts and the Future of Automotive

Time.news Editor: Welcome, Dr.Evelyn Reed, to Time.news. Your expertise in automotive industry transformations is highly valued. audi’s recent declaration regarding job cuts has sparked considerable discussion. Can you provide our readers with some context on this situation?

Dr. Evelyn Reed, Automotive Industry Analyst: Thank you for having me. Audi’s move to reduce its workforce by up to 7,500 positions in Germany by 2029 is indeed meaningful. This decision is primarily driven by the immense financial demands of transitioning to electric vehicle [EV] production. The industry is undergoing a massive transformation, and conventional automakers like Audi must adapt rapidly to remain competitive. Cost optimization, in this case, is about freeing up capital to pour into EV technology and manufacturing [[2]].

Time.news Editor: So, these job cuts are a direct consequence of Audi’s electrification strategy?

Dr. Reed: Precisely. Audi aims to save around €1 billion annually through these cuts, which will then be reinvested into its German facilities, with a projected €8 billion investment over the next four years.The goal is to streamline operations and enhance efficiency as they pivot towards a more lasting future. The Volkswagen Group, as a whole, is looking at significant reductions, around 48,000 job cuts, signaling an industry-wide shift.

Time.news Editor: Can you elaborate on the implications for the workforce and the German automotive industry in general?

Dr. Reed: The impact on the workforce is a major concern. Job security is threatened in a sector known for its stability. Unions worry that EV production may shift to regions with lower labor costs, further exacerbating the issue.However, we need to see these changes in the context of a broader transformation, companies such as Audi must innovate if they are to improve sales in this new automotive era [[3]].

Time.news Editor: Audi has been making strides with EV production. Can you discuss their progress and the challenges they face?

Dr. Reed: As 2019, Audi has been strategically reducing its production workforce to finance its electric vehicle transition. While they aim to boost profit margins, they faced a dip in operating margins in the first three quarters of 2024. This highlights the difficulty in balancing investment in new technology, and pressure for improved profits. the plan to produce a new electric entry model at its Ingolstadt factory signifies their commitment to adapting to consumer preferences for EVs.

Time.news Editor: Competition in the EV market is fierce. How is Audi positioned against both established rivals and emerging players?

Dr. Reed: Audi is facing intense pressure from established automakers and new entrants,especially from Asia and the United States. This competitive landscape necessitates strategic partnerships and technology collaborations. Leveraging new technologies like artificial intelligence and advanced manufacturing processes will be crucial for enhancing operational efficiency and achieving a sustainable production model. Companies may need to change the location of production to better appeal to their customers, such as in the U.S. [[1]].

Time.news Editor: What advice would you give to workers affected by these layoffs and to those seeking a career in the automotive industry during this period of change?

Dr. Reed: For those affected by layoffs, I would strongly recommend exploring reskilling and retraining programs.The EV sector demands new skills, and transitioning to roles in areas like battery technology, software growth, and EV infrastructure is a viable option. For those entering the industry, focus on acquiring these in-demand skills. As the automotive industry goes through a crisis from the EV revolution [[2]],retraining programs will be essential in helping the workforce adjust.

Time.news Editor: Looking ahead, what are the long-term implications of these changes for the automotive industry?

Dr. Reed: The automotive industry faces a period of uncertainty and chance. The shift to electric vehicles is reshaping manufacturing processes, supply chains, and the workforce. The industry must reconcile technological innovation with socio-economic responsibilities, ensuring that workers are not left behind. The success of companies like Audi will depend on their ability to balance these factors and navigate this rapidly changing surroundings.