Although ancient and widely used, homeopathy is still shrouded in mystery. How are the drops, tinctures and ointments prepared? And what is the purpose of shaking, macerating and potentiating? The process, from marigold to bottle.

The starting point of this story are some bucolic farmlands deep in the French countryside, in the undulating valley of the Drôme, where organic farmer David Vieux grows marigolds on elongated fields. He is one of the suppliers of a homeopathy company, which processes its proceeds into ointments, balms and drops.

1. Picking by hand

Marigold or calendula appears to be a very versatile but anything but demanding plant that is easy to grow and guarantees a long-lasting harvest. Provided there is sufficient heat and not too much moisture, fresh petals can be harvested from spring and as long as it does not freeze. This is done completely manually, in order to bruise the delicate leaves as little as possible.

This rapid flowering is good news, given the many beneficial properties attributed to this plant. For centuries, the marigold, which is rich in antioxidants such as carotene, polyphenols and flavonoids, has been used medicinally for minor and major complaints, thanks to its disinfecting, wound healing and anti-inflammatory effect. These special characteristics were already noticed by the German naturopath Hildegard von Bingen, who describes them in her Medieval herbal book.

It is no coincidence that this plant is also used in homeopathy. To be eligible for this, the flowers must meet a number of requirements. For example, they must be grown completely organically and not be located in the vicinity of highways or polluting industry, to prevent air pollution from affecting their properties.

2. Botanical control

The same day, the colorful field yields leave in refrigerated trucks for the high-tech production site of the homeopathy company near Lyon, about 100 km away, where processing will start as soon as possible. The cultivation and picking are artisanal, and the further conversion into a homeopathic remedy is so industrial. The same strict hygiene standards apply in this factory as other pharmaceutical or food manufacturers.

Upon arrival, a thorough botanical check follows, which not only checks whether the leaves are sufficiently fresh and moist, but also measures their radioactivity via samples. It is rather rare, but sometimes actual radioactive contamination is found on plants and flowers, which immediately makes them unsuitable.

3. Mixture

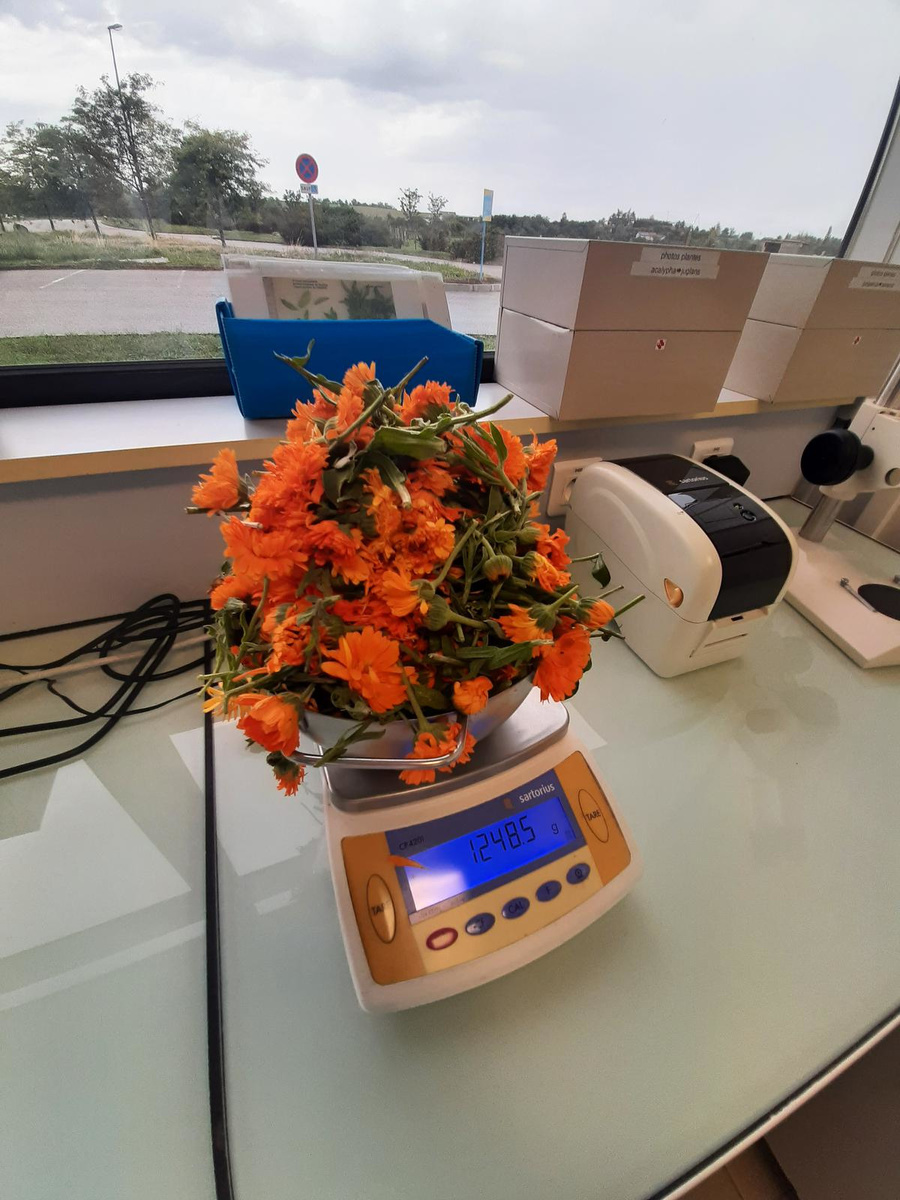

What follows is a combination of an automated industrial process and a traditional touch. The approved flowers, like other raw materials, are weighed and checked for the presence of foreign elements.

A sample then goes into a machine that determines the moisture content and, based on that, calculates how much alcohol and water must be added to produce the mother tincture, a highly concentrated solution that preserves all the benefits of the plant.

The petals then disappear into a cutting machine that shreds them, after which the mixture of plants and an alcohol-water solution goes to the maceration zone.

4. Shake and stir

In large sealed stainless steel vats, the brew continues to steep (macerate) for weeks. Typically with homeopathic preparations, the mash in the vessels is stirred at regular intervals for better mixing. That manual stirring and shaking seems bizarre, but according to the guidelines of the homeopathic pharmacopoeia, this process stimulates the plants to release their beneficial properties to the alcohol-water solution.

5. Pressing, filtering and potentiating

After an average of 10 to 30 days of soaking and shaking, the mixture ends up in a press machine, after which the cloudy solution is filtered several times to a clear liquid, the primal or mother tincture. This is checked again for the presence of sufficient active substances. Not unimportant, since many dilutions follow in homeopathy.

6. Supplements and cosmetics

Only when the highly concentrated mother tincture of the marigold is approved is this basic raw material ready to be used for the production of food supplements and cosmetics. The cream, mousse and lip balm mainly improve irritated or very dry skin, while drops of the calendula extract are used for digestive complaints, to improve circulation and support the liver.

Regular scientists emphasize that the effect of homeopathy is still not scientifically proven.

We visited the production chain of homeopathy company Boiron in France.

Read also: Healing homeopathy

The starting point of this story are some bucolic farmlands deep in the French countryside, in the undulating valley of the Drôme, where organic farmer David Vieux grows marigolds on elongated fields. He is one of the suppliers of a homeopathy company, which processes its proceeds into ointments, balms and drops. Marigold or calendula appears to be a very versatile but anything but demanding plant that is easy to grow and guarantees a long harvest. Provided there is sufficient heat and not too much moisture, fresh petals can be harvested from spring and as long as it does not freeze. This is done completely manually, in order to bruise the delicate leaves as little as possible. This rapid flowering is good news, given the many beneficial properties that are attributed to this plant. For centuries, the marigold, which is rich in antioxidants such as carotene, polyphenols and flavonoids, has been used medicinally for minor and major complaints, thanks to its disinfecting, wound healing and anti-inflammatory effect. These special characteristics were already noticed by the German naturopath Hildegard von Bingen, who describes them in her Medieval herbal book. It is no coincidence that this plant is also used in homeopathy. To be eligible for this, the flowers must meet a number of requirements. For example, they must be grown completely organically and not be located in the vicinity of highways or polluting industry, to prevent air pollution from affecting their properties. The same day, the colorful field yields leave in refrigerated trucks for the high-tech production site of the homeopathy company near Lyon, such a 100 km away, where processing will start as soon as possible. The cultivation and picking are artisanal, and the further conversion into a homeopathic remedy is so industrial. The same strict hygiene standards apply in this factory as with other pharmaceutical or food manufacturers. A thorough botanical check follows on arrival, which not only checks whether the leaves are sufficiently fresh and moist, but also measures their radioactivity via samples. It is rather rare, but sometimes radioactive contamination is actually found on plants and flowers, which immediately makes them unsuitable. What follows is a combination of an automated industrial process and a traditional touch. The approved flowers, like other raw materials, are weighed and checked for the presence of foreign elements. A sample then goes into a machine that determines the moisture content and, based on that, calculates how much alcohol and water must be added to produce the mother tincture, a highly concentrated solution that preserves all the benefits of the plant. The petals then disappear into a cutting machine that shreds them, after which the mixture of plants and an alcohol-water solution goes to the maceration zone. Typically with homeopathic preparations, the mash in the vessels is stirred at regular intervals for better mixing. This manual stirring and shaking seems bizarre, but according to the guidelines of the homeopathic pharmacopoeia, this process stimulates the plants to release their beneficial properties to the alcohol-water solution. After an average of 10 to 30 days of soaking and shaking, the mixture ends up in a pressing machine , after which the cloudy solution is filtered several times to a clear liquid, the primal or mother tincture. This is checked again for the presence of sufficient active substances. This is not unimportant since many dilutions follow in homeopathy. Only when the highly concentrated mother tincture of the marigold is approved is this basic raw material ready to be used for the production of nutritional supplements and cosmetics. The cream, mousse and lip balm mainly improve irritated or very dry skin, while drops of the calendula extract are used for digestive complaints, to improve blood circulation and support the liver. Mainstream scientists emphasize that the effect of homeopathy is still not scientifically proven . We visited the production chain of homeopathy company Boiron in France. Read also: Healing homeopathy