There is a person who has been at the center of the semiconductor industry for over 70 years, from its inception to the present. He is also a revolutionary who changed the way this huge industry works. This is Maurice Chang, the founder of Taiwan’s TSMC, the world’s largest foundry (semiconductor consignment production) company.

How did Maurice Chang, a poor immigrant who majored in mechanical engineering, become a pioneer who reshaped the flow of the global technology industry? What made him make choices and take on challenges that were different from others? The key to understanding TSMC Maurice Chang’s past storyLet’s take a look.

*This article is an online version of the Deep Dive newsletter published on the 1st. Subscribe to Deep Dive’s newsletter, ‘Economic news you’ll fall in love with as you read it.’

Self-taught engineer in semiconductors

In 1949, an 18-year-old student from China entered the English Department at Harvard University in the United States. His name was Zhang Zhongmou (張忠謀), later Maurice Chang. He recalls that the United States, where he left his country suffering from war and poverty, “was heaven.” He may not have known it at the time, but it had been about a year since the transistor, which replaced glass vacuum tubes, had been invented at Bell Laboratories in the United States.

The following year, he transferred to MIT (Massachusetts Institute of Technology), thinking that he needed to learn technology to get a good job. My major was mechanical engineering, which was popular at the time. After completing his master’s degree in 1955, four companies offered him employment. The most famous and attractive place is Ford Motor Company. But Sylvania, a less famous electronics company, offers a monthly salary of $480, just one dollar more than Ford. Maurice Chang is exciting I called Ford and asked if they could set my salary to $480 a month, but they immediately said no. I was rejected. As fate would have it, he joined Sylvania and encountered the fledgling semiconductor industry.

![He has been at the center of the semiconductor industry for 70 years… Maurice Chang TSMC founder story[딥다이브] He has been at the center of the semiconductor industry for 70 years… Maurice Chang TSMC founder story[딥다이브]](https://dimg.donga.com/wps/NEWS/IMAGE/2024/11/01/130342628.1.jpg)

His first task is to increase transistor yield (percentage of normal products). He discovered that the heat from soldering damaged transistors, and figured out a way to connect wires using indirect heat. The problem was solved through mechanical engineering.

He decides to study semiconductor theory for work. I used the book William Shockley, the Nobel Prize winner who invented the transistor, as my textbook. Self-studying wasn’t easy. He learned that the factory’s older senior engineer spent hours drinking at the hotel bar every night. So every day after work, I study with a book, Whenever I don’t know something, I go to the hotel bar, buy the engineer a drink, and ask him questions.do. Maurice Chang recalled, “He (senior engineer) was my teacher in electronics.”

Morris Chang, who gained expertise in semiconductors, moved to designing transistors. While attending technology conferences and identifying trends, he came to a realization. Sylvania has no vision in semiconductors. So, when TI (Texas Instruments) offered to hire him in 1958, he left without hesitation. He wrote in his autobiography about the downfall of his first job: “From the beginning, the semiconductor industry has been a fast-moving and unforgiving industry. “If you fall behind, it becomes quite difficult to catch up.”

Shake up the market with aggressive pricing policies

At the time, TI was an emerging technology company. In 1958, TI researcher Jack Kilby (winner of the 2000 Nobel Prize in Physics) invented a new technology that would change the world. It is an integrated circuit (IC).

When Maurice Chang had just joined the company, TI was having trouble with the yield of the transistor production line ordered by IBM. At the time, the yield was almost 0. Sometimes it was as high as 2-3%. In short, only defective products were being produced. He was in charge of this disastrous transistor production line.

and After three months, the yield jumps to 25-30%. He explains the secret this way: “I tried changing the recipe several times to make sense. Basic knowledge of device physics was needed to estimate the appropriate temperature, pressure, and dopant (impurity). That’s what I became good at through self-study and experience in Sylvania. “It may be ‘ancient’ by today’s standards, but at the time, the ability to achieve good yields in transistors was invaluable.”

This transistor was a huge success for TI, and even the president of TI knew his name. The company offered to sponsor him for a doctoral degree. He received salary and tuition support and completed his doctorate in electrical engineering at Stanford University in two and a half years. Afterwards, he rose through the ranks at TI, becoming the general manager of integrated circuits in 1967.

During this time he It completely changes the way semiconductors are priced. This is one of the revolutionary changes he brought about in the semic

How was the selling price of semiconductors determined at the time? Semiconductor manufacturing is a capital-intensive business. Because the initial capital was so high, manufacturers tried to recoup costs as quickly as possible by charging prices as high as possible.

However, Maurice Chang, who had a lot of production line experience, thought that was wrong. Because new production lines start with very poor yields. The only way to increase yield is to continue modifying and training while producing a lot. But what if the product price is too expensive? Since there are no customers looking for it → production cannot be increased → the yield has no choice but to remain the same.

He creates a ‘learning curve pricing’ model with Boston Consulting, which was a small company at the time. By setting the chip price much lower than the initial cost or market price, the production line is operated at maximum capacity. It’s a strategy. Although you sacrifice initial profitability, you can greatly shorten the time to increase yield and put pressure on competitors.

This strategy, which was initially criticized as foolish, is effective. TI’s semiconductor market share has increased, and it has emerged as the world’s largest integrated circuit company. Learning curve pricing models are now the standard in the semiconductor industry.

Failure and frustration… Leaving a 25-year job

He was a successful executive who aspired to one day become CEO of TI. So the company entrusted him with a new important task in 1978. Appointed Vice President of Consumer Products. Since the company demonstrated outstanding capabilities in the semiconductor division, it was expected that it would be able to revive the calculator and wristwatch businesses, which were underperforming. So what was it like?

Yes, you are wrong. B2B and B2C are completely different fieldsIt was. As it lost out to cheaper Japanese products, inventory piled up in warehouses, and the watch division was closed in 1981. It was an abject failure. Maurice Chang says: “The customer groups, the markets, and what was needed to get ahead were completely different. The semiconductor business requires only technology and cost. In consumer business, technology is helpful, but appealing to consumers is important.”

In 1981, Maurice Chang was effectively demoted to the position of ‘Director of Quality and Workforce Efficiency’. he is “I was still the senior vice president, but I felt like I was essentially put out to pasture.”And I look back. Moreover, in 1980, IBM adopted Intel’s processor rather than TI’s for its new personal computer (PC). TI’s semiconductor business began to decline. ‘I can’t do anything interesting here anymore. Thinking that he couldn’t even become a CEO, he left TI in 1983.

His resignation was announced in a newspaper article, and calls to recruit him poured in. He holds the position of President and COO (Chief Operating Officer) of General Instruments, a fairly large company. I am leaving here after about a year. General Instruments was a type of private equity fund-style company that acquired various semiconductor businesses

Business plan born in four days

To Maurice Chang, a wealthy 54-year-old unemployed man in 1985. The Taiwanese government offers him the position of chairman of the Industrial Technology Research Institute (ITRI), a non-profit research institute.do. In fact, he was from mainland China and had little to do with Taiwan. He had already acquired American citizenship in 1962 and his identity was American. To him, Taiwan was an unfamiliar country and he had nothing. His coworkers and his wife at the time (his first wife) jumped and asked why he was going to Taiwan.

But he eagerly accepts this offer. He explains why: “It was a completely new kind of job for me and a completely different environment. Everything seemed so different to me. By then I was pretty financially stable. I could live my whole life without receiving a salary. So the compensation was much lower, but I came because Taiwan seemed so new and challenging. “I believe you should follow your own interests, not where the big money is.”

A few weeks after coming to Taiwan, Minister of Economic Affairs Li Guoding, now known as the ’Father of Taiwan’s Economic Miracle’, called him and said: “You have a lot of experience running a large semiconductor company, so I think you would be a good fit to start a new semiconductor company in Taiwan. Please let me know how much money the Prime Minister needs within a week or so.”

The next day, Minister Li Guoding again asks the Prime Minister to make a presentation three days later rather than a week later. In fact, Maurice Chang didn’t have to wait a week. Because I quickly got an idea of what to do. like that The idea of becoming the world’s first pure foundry company was born in four days.do.

Changed the semiconductor industry and changed the world

At the time, all of the world’s leading semiconductor companies produced their own products. Almost all of them were comprehensive semiconductor companies called IDM. A fabless company that only designs and leaves production to other companies? In fact, it almost didn’t exist in the mid-1980s. Even in the early 1990s, their number was small, less than 100. Jerry Sanders, co-founder of AMD, said this in a lecture in 1992. “Real men are fab”(This is a disparaging term for poor fabless competitors who do not have their own factories, but AMD also sold its factories in 2008 and became fabless).

However, in 1985, Maurice Chang planned a pure foundry business that would only produce chips upon customer orders. There were no customers (fabless companies) to order from anywhere. In other words, they said they would create a new market that did not exist at all.

What on earth did he believe in to take on such a reckless challenge? His insight was twofold.

1. The only thing Taiwan was good at was manufacturing.

Maurice Chang speaks very coldly. “What strengths do we (Taiwan) have? The bottom line is that there are very few. we are There are few strengths in research and development, circuit design, IC product design, sales and marketing, and intellectual property rights. Taiwan’s only potential strength was manufacturing. “The answer to suit its strengths and avoid other weaknesses was pure foundry.”

2. I saw the possibility of opening a new market.

He reflects on his experiences at TI and General Instruments. “I see a lot of integrated circuit designers wanting to leave the company and start their own business. The reason they couldn’t leave was because they couldn’t raise enough money to start a company.no see. “They didn’t have enough money to build a wafer fab.” What if you could outsource manufacturing to someone else without building your own production line? Start-up capital will be reduced by 1/100. This is why a pure foundry company was needed.

So Maurice Chang made a presentation. The capital required to establish the world’s first foundry company in Taiwan is $220 million. The Taiwanese government provided half, but significant external investment was required. Maurice Chang moved to the United States and met Intel and TI. All answers were ‘no’. Fortunately, the last contact Dutch company Philips invested $58 million (28% stake)obtains. This was also the beginning of a relationship with ASML, another Dutch company spun off from Philips. The remaining shares are filled by the Taiwanese government by stabbing companies.

In the summer of 1987, Taiwan Semiconductor Manufacturing Company (TSMC) was established with 50 employees. What shares did Maurice Chang, who served as chairman of TSMC, receive at the time? It was 0. There was not a single share of stock received as compensation for establishment. A few years later, he used his savings to buy a 0.5% stake in TSMC, now worth $5 billion.

Maurice Chang’s foresight was correct. The number of fabless companies in the world, which was about 20 in 1987, has now increased to thousands. NVIDIA, Qualcomm, and Broadcom are customers that have joined hands with TSMC from the beginning. Nvidia CEO Jensen Huang said, “I was excited when I learned about Morris and TSMC.” “NVIDIA was not possible without TSMC”It has been said several times.

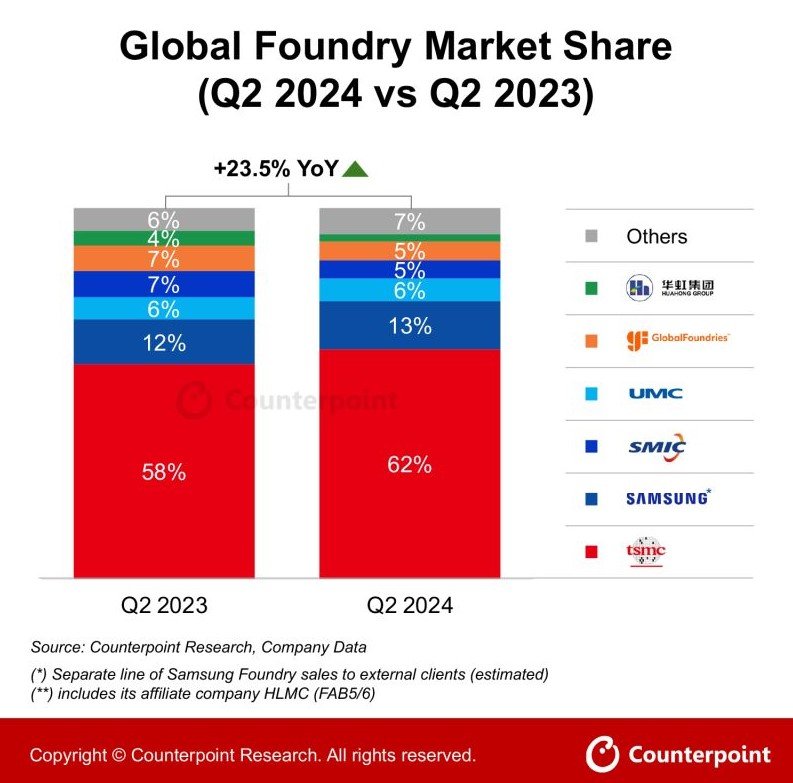

TSMC is dominating the semiconductor business in a way no other company has ever done. TSMC’s share in the global foundry market in the second quarter of this year was 62%. As time goes on, the power increases.

Regardless of how long this dictatorial system will continue, The emergence of pure foundry TSMC is a revolution in the semiconductor industry.It was. It completely changed the landscape of this industry. Former Chairman Maurice Chang, who retired in 2018, attended the TSMC Annual Sports Festival a few days ago at the age of 93 and warned, “

“Semiconductor free trade is dead.” As Chris Miller, author of ‘Chip War,’ said, he “The most underrated businessman of the last 100 years.”It may be. By. Deep Dive

Morris Chang is often portrayed in the Korean media as a patriotic figure who ‘fostered the semiconductor industry for his country.’ In fact, he made it clear in an interview with the New York Times last year that his identity is American. As I looked back at his past interview records, I thought that perhaps the frustration of hitting the glass ceiling at a large American company had rekindled his fire. It’s not patriotism, but pride is the real driving force. For reference, it is said that the second part of his autobiography (which contains the story after the establishment of TSMC) will be published in Taiwan at the end of this month. Once it is translated, I will read it and share the interesting content in another letter.

*This article is an online version of the Deep Dive newsletter published on the 1st. Subscribe to Deep Dive’s newsletter, ‘Economic news you’ll fall in love with as you read it.’

St this year, reflecting on the journey that transformed Taiwan into a global semiconductor powerhouse. The success of TSMC not only solidified Taiwan’s position in the tech industry but also revolutionized the entire semiconductor landscape.

Maurice Chang’s vision of a pure foundry model was initially met with skepticism. Traditional Integrated Device Manufacturers (IDMs) believed that producing chips in-house was the only viable path. However, Chang identified a significant gap in the market, recognizing that many chip designers lacked the capital to establish their own manufacturing facilities. By providing a platform where these designers could outsource production, TSMC opened up new opportunities for innovation and entrepreneurship.

The strategic decision to focus solely on manufacturing allowed TSMC to specialize and dominate the foundry market. Innovative companies like NVIDIA and Qualcomm benefited immensely from TSMC’s capabilities, leading to groundbreaking advancements in technology. The collaboration between TSMC and these fabless companies fueled the rapid growth of the semiconductor industry, enabling the development of powerful chips that are central to modern computing.

As the semiconductor market evolved, TSMC consistently pushed the boundaries of manufacturing technology, investing billions into research and development. This dedication to innovation has kept TSMC at the forefront of the industry, allowing it to maintain a staggering market share and establish itself as a cornerstone of the global technology supply chain.

The story of TSMC is a testament to the power of vision, resilience, and the ability to identify and capitalize on emerging market needs. Maurice Chang’s journey from a semiconductor executive to the founder of the world’s leading foundry company serves as an inspiration for entrepreneurs and innovators worldwide. As TSMC continues to shape the future of technology, its legacy will undoubtedly endure as a revolutionary force in the semiconductor industry.