Hyundai Movex, a smart logistics solutions company, announced on the 29th that it is increasing its performance in the global market by leading the way with advanced logistics technology.

Hyundai Mobis, which started as the logistics division of Hyundai Elevator in 1989, was separated as an independent corporation in 2017. In 2018, it merged with IT affiliate Hyundai UNI to strengthen its HW (machinery and equipment) and SW (control system) capabilities.

Smart logistics, which is a convergence of various industries such as machinery, equipment, and IT, is emerging as a promising new industry. Recently, the introduction of smart logistics is rapidly increasing in new growth industries such as secondary batteries, pharmaceuticals/bio, and e-commerce.

In the smart logistics business, it is important to have a good understanding of the industrial site and consulting capabilities that apply the optimal automation system. This is because smart logistics solutions can vary depending on the industrial environment and on-site conditions. A Hyundai Movex official said, “We are providing total smart logistics solutions such as design, production, construction, and maintenance as a one-stop service, combining know-how accumulated from long-term business experience, professional manpower, and advanced consulting programs.” He continued, “Based on the reference of supplying smart logistics solutions for 35 years, we have established an unrivaled position in the domestic market.”

Hyundai Mobis has also pursued bold business diversification, including global expansion. Last year, it entered the secondary battery smart logistics business and achieved annual orders of over 400 billion won, mainly in North America. It was the largest order performance since its establishment.

This year, we have expanded our smart logistics business area from secondary battery cells to material processes. ▲ In January, we successfully received large-scale orders, such as the EcoPro BM Canadian cathode material plant and the US cathode material plant of a global secondary battery material company in April. In the first half of the year, we have already exceeded half of the annual orders from last year. In addition, we are achieving order results in the tire, distribution, food, pharmaceutical, and bio industries.

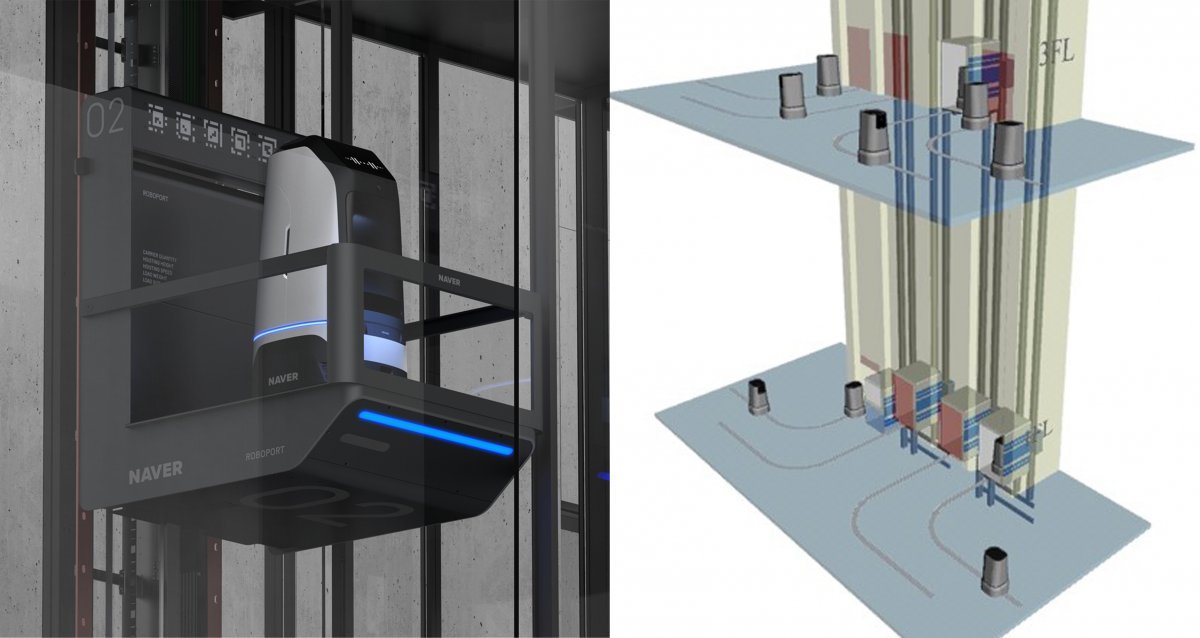

Hyundai Mobis invested approximately 22 billion won in a 2,000-pyeong site in 2019 to build a large-scale Cheongna R&D Center. The goal here is to produce significant development results that will serve as the foundation for future growth. The robot-only elevator Roboport of Naver’s new headquarters building 1784, which was unveiled in 2022, is a representative achievement of the Cheongna R&D Center. It is the world’s first robot-only elevator jointly developed with Naver and Naver Labs for approximately two years and moves over 100 service robots.

The Cheongna R&D Center contributed to adding a wide range of smart logistics lineups in a short period of time, including its main business, AS&RS (automated receipt and retrieval warehouse system), as well as new concept return, shuttle, classification, and picking solutions. In particular, it contributed to the development of AGV (automated transport vehicle) and advancement of robot control system, which are also connected to Hyundai Movex’s future market. AGV and AMR (autonomous mobile robot) are evaluated as game changers in the smart logistics market that can upgrade conveyor-centered mechanical transport automation to IT-centered intelligence. After five years of establishing the Cheongna R&D Center, Hyundai Movex has introduced dozens of AGVs made with its own technology and is deploying them in industrial sites such as secondary batteries, pharmaceuticals, and bio. It also succeeded in localizing gantry robots (picking and transport orthogonal robots), which had previously relied on imports, and supplied them to global tire companies.

According to Hyundai Movex, the smart logistics industry is actively promoting the introduction of robots and AI as part of innovation to move beyond automation and intelligence to unmanned operation. Accordingly, Hyundai Movex held the ‘1st Developer Meeting’ last July. It was a place to discuss the advancement of AI and robot technology and the direction of development. R&D researchers shared key future technology trends such as big data, predictive maintenance, and demand forecasting, and explored ways to integrate AI, robots, and smart logistics.

Doik Han, CEO of Hyundai Mobis, is holding an idea contest for employees to come up with ideas for AI-based technology development and work improvement, and is also sequentially promoting the introduction of ChatGPT.

A Hyundai Mobis official said, “In the midst of the rapidly changing industrial paradigm, smart logistics will grow into one of the key future industries,” adding, “We will strive to become a smart solution leader that encompasses all industries beyond logistics.”

Reporter Lee Han-gyu [email protected]

-

- great

- 0dog

-

- I’m sad

- 0dog

-

- I’m angry

- 0dog

-

- I recommend it

- dog

Hot news right now

2024-08-30 10:40:28