2024-07-03 17:13:57

Completion of joint venture factory ‘HLI Green Power’

‘Indonesian Electric Vehicle Ecosystem Completion Ceremony’ Held

Co-hosted by President Joko Widodo and the Indonesian government

Local procurement and production starting from battery cells to electric vehicles

‘Kona Electric’ begins mass production in Indonesia

“Laying the foundation for building an electric vehicle ecosystem beyond Indonesia and ASEAN”

Hyundai Motor Group has completed its electric vehicle production system in Indonesia. With the completion of the battery plant in collaboration with domestic battery company LG Energy Solution, local procurement and production of everything from battery cells to electric vehicles has become possible. In particular, the newly completed battery plant is close to Hyundai Motor Company’s Indonesian finished vehicle plant (30 minutes away), so it is expected to have effects comparable to the integration of local electric vehicle production. Hyundai Motor Group expects that by establishing a local integrated production system from batteries to electric vehicles, it will be able to secure a strategic advantage in the ASEAN electric vehicle market beyond Indonesia.

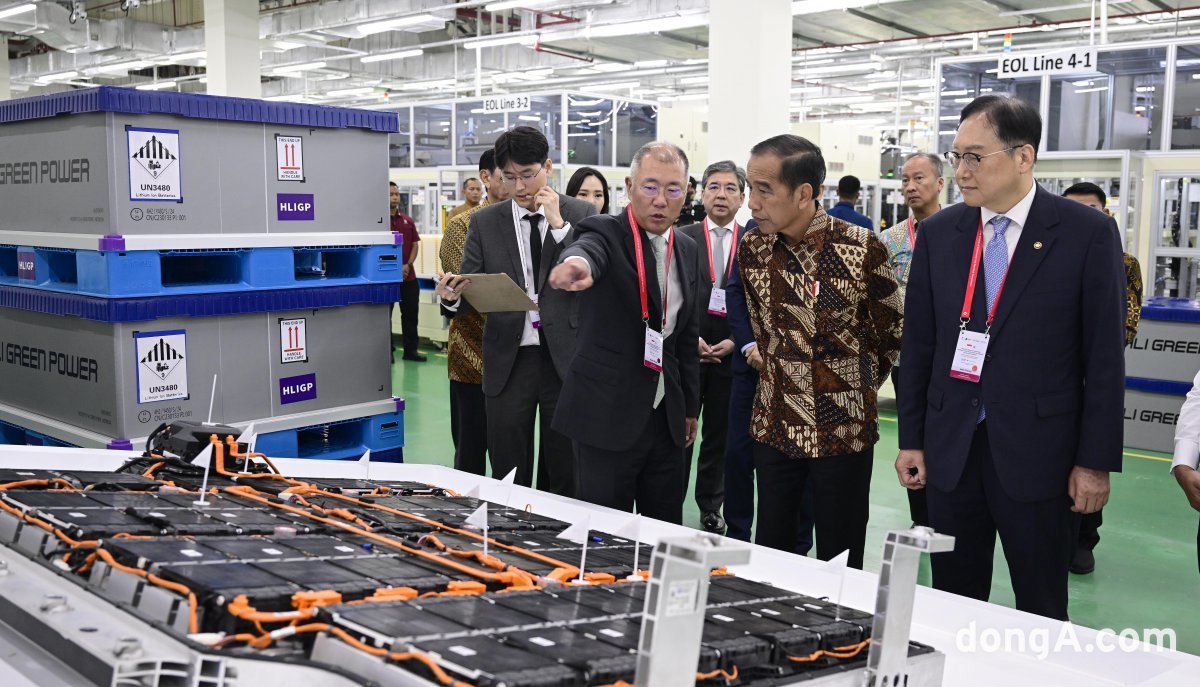

On the 3rd (local time), Hyundai Motor Group held an event to celebrate the completion of the LG Energy Solution joint battery cell factory ‘HLI Green Power (Hyundai LG Indonesia Green Power)’ located in Karawang New Industry City (KNIC), Indonesia and the mass production of Kona Electric. The Indonesian government also participated and held a ‘Ceremony to Celebrate the Completion of the Indonesian EV Ecosystem’.

The event was attended by key officials from both companies, including Hyundai Motor Group Chairman Chung Eui-sun, Hyundai Motor President Chang Jae-hoon, and LG Energy Solution President Kim Dong-myung, as well as South Korea’s Trade Negotiation Headquarters Director-General Chung In-kyo and Ambassador to Indonesia Lee Sang-deok. From the Indonesian government, President Joko Widodo, Coordinating Minister for Maritime Affairs and Investment Luhut Binsar Pandjaitan, Investment Minister Bahlil Lahadalia, Industry Minister Agus Gumiwang Kartasasmita, Public Enterprises Minister Erick Thohir, and West Java Governor Bey Triadi Machmudin also attended.

In his congratulatory remarks, Indonesian President Joko Widodo said, “We have laid the foundation for playing an important role in the global electric vehicle battery and electric vehicle ecosystem,” and added, “I would like to express my gratitude to Hyundai Motor Group and Chairman Chung Eui-sun, and LG Energy Solution and President Kim Dong-myung for deciding on this important project.” He added, “Hyundai Motor Group and LG’s integrated battery ecosystem will also have a positive impact on the development of relations between Korea and Indonesia.”

On this day, President Joko Widodo held a ceremony to assemble battery cells produced by HLI Green Power into battery modules and packs and to sign the first Kona Electric vehicle produced in Indonesia. In 2019, President Widodo also attended the investment agreement ceremony for the Indonesian plant held at Hyundai Motor Company’s Ulsan plant and signed the Kona Electric vehicle.

“The completion of the Indonesian battery cell plant and the mass production of the Kona Electric are the fruits of collaboration between Hyundai Motor Group and Indonesia,” said Chung Eui-sun, Chairman of Hyundai Motor Group. “They symbolize our strong partnership and prove that we are co-creating the future of the electric vehicle ecosystem not only in Asia but also around the world.” He added, “We expect that the vehicles produced and sold in Indonesia will set new standards for potential customers in the Southeast Asian region, contribute to the revitalization of the Indonesian electric vehicle industry, and provide new economic opportunities for the entire Southeast Asia.”

He also mentioned future business areas beyond electric vehicles. Chairman Chung said, “By strengthening cooperation with Indonesia, we will pioneer new areas together, from resource-recycling hydrogen solutions to future air mobility,” and “I hope to create the future together in the spirit of ‘Membuka jalan baru (Pioneering a new path)’.”

The significance of this factory completion is that it establishes an electric vehicle production ecosystem that is comparable to vertical integration from batteries to finished vehicles in an overseas base rather than a domestic one. It is expected that an integrated electric vehicle production system will be completed in the United States, the world’s largest market, soon.

Hyundai Motor Group emphasized that by completing the local electric vehicle production system, it is opening up the future of the electric vehicle ecosystem in the global market. The battery cells produced at HLI Green Power, which was completed on this day, will be supplied to the adjacent Hyundai Motor Company plant and installed in the Kona Electric, which is entering local production in Indonesia.

Indonesia is the world’s fourth most populous country and a key member of the Association of Southeast Asian Nations (ASEAN). It is evaluated as having explosive growth potential. In addition, it is considered a hub for the raw materials supply chain as it has the world’s largest reserves and mining volume of nickel, a key mineral for electric vehicle batteries.

Hyundai Motor Group Establishes Core Foundation for ASEAN Electric Vehicle Ecosystem

Hyundai Motor Group emphasized that with the completion of this joint venture plant, it has laid a core foundation for creating an electric vehicle ecosystem in ASEAN beyond Indonesia. It stated that, like in Korea, it is establishing a local electric vehicle ecosystem in Indonesia that encompasses raw material procurement, battery and finished vehicle production, expansion of charging systems, and battery recycling, and is establishing a strategy to secure leadership in the ASEAN electric vehicle market. In particular, it was evaluated that with the local mass production of everything from battery cells, which are the core of the electric vehicle ecosystem, to battery packs and finished vehicles, it will be possible to expand the front and rear industrial ecosystems more flexibly.

HLI Green Power broke ground in September 2021, conducted test production last year, and began producing battery cells in the second quarter of this year. It has electrode processes, assembly processes, and activation processes on a site of 320,000 m2, and has an annual battery cell production capacity of 10 gigawatt-hours (GWh), enough for more than 150,000 electric vehicle batteries. Battery cells are the most basic components of electric vehicle batteries. Cells are assembled to form modules, modules are connected, and various components connected to the main devices of electric vehicles are added to complete a battery pack that can be mounted on an electric vehicle.

The type of battery cell produced by HLI Green Power is a high-performance NCMA lithium-ion battery cell that combines high-content nickel (N, high nickel), cobalt (C), manganese (M), and aluminum (A). It is installed not only in electric vehicles produced locally in Indonesia, but also in electric vehicles produced in other regions.

The Kona Electric, which has recently entered mass production for the first time locally, is scheduled to be released in the Indonesian market on the 17th. The Kona Electric is the second electric vehicle to be produced at Hyundai Motor Company’s Indonesian plant, following the Ioniq 5. Hyundai Motor Company’s strategy is to foster the Kona Electric as Indonesia’s representative electric vehicle.

In addition, Hyundai Motor Group is also working with various companies to secure a stable supply chain for key raw materials for electric vehicle batteries, such as nickel, in Indonesia. It is also accelerating the construction of charging infrastructure in local public places and conducting research on ways to utilize used batteries. It is promoting the creation of an overall ecosystem beyond electric vehicle sales, and these moves are expected to have a positive impact on ASEAN and the global market.

Indonesia’s top brand leaps forward… Expanding electric vehicle lineup and experience

Indonesia is actively fostering related industries, such as announcing a plan to produce 600,000 electric vehicles by 2030. It also provides benefits when purchasing electric vehicles. If you purchase an electric vehicle in Indonesia, you will be excluded from the two-part system that is being applied to relieve traffic congestion, and you can be exempted or reduced from the registration tax of up to 12-15% in major cities such as Jakarta. In the case of local companies, if they use local parts and labor to meet the localization rate conditions, the luxury tax (15%) on the produced electric vehicles will be exempted and a temporary 10% VAT reduction will be provided. The government is also converting more than 10,000 vehicles per year, or a total of 130,000 vehicles, to electric vehicles from 2021 to 2030.

In terms of local electric vehicle demand, sales volume last year was around 18,000 units, which is still only 2% of the total. However, Hyundai Motor Group is forecasting that through continuous electric vehicle conversion policies, it will have a double-digit share by 2030. This means that there is ample growth potential. Meanwhile, Chinese electric vehicles are also pushing to enter Indonesia, so competition in the electric vehicle market is expected to intensify in the future.

Hyundai Motor Company is the first brand in Indonesia to have a local mass production system, and its strategy is to lead the Indonesian electric vehicle market by building a positive image and providing a diverse lineup of electric vehicles and specialized customer experiences. In terms of the electric vehicle lineup, the plan is to successfully establish the Kona Electric to lay the foundation for popularizing electric vehicles and to secure the status of a premium electric vehicle brand by introducing the IONIQ 6 along with the IONIQ 5. In the future, the company plans to continue introducing electric vehicle models suitable for the Indonesian market.

In addition, we plan to increase customer satisfaction with after-sales service by establishing specialized electric vehicle mechanics and dedicated maintenance facilities, and to build a mobile app-based charging infrastructure centered around dealer showrooms. We are also planning to operate programs such as electric vehicle-specific warranties and free inspections.

On this day, Hyundai Motor Company President Chang Jae-hoon also mentioned the need for low-priced electric vehicles in order to conquer the ASEAN market. President Chang said, “If you look at the overall product composition of the ASEAN market, low-priced electric vehicles are also a necessary part, and we are also making plans for low-priced vehicles.” He explained that the Ioniq 5 and Kona Electric, which are currently being produced locally, are models that lead the brand and also play a role in establishing the brand as a premium electric vehicle brand. He emphasized that while the local sales target for the Kona Electric is being aggressive, market share is more important. He also expressed his wariness of Chinese electric vehicles. President Chang said, “Chinese cars are strengthening their offensive by prioritizing price, so we will work to secure product competitiveness and lead the market.”

It was revealed that the batteries produced at the Indonesian joint venture will be installed in vehicles sold not only in Indonesia but also in other regions. In Korea, CEO Jang Jae-hoon explained that the Casper Electric, which was first unveiled at the 2024 Busan Mobility Show held recently at BEXCO in Busan, will use batteries produced in Indonesia. It was also revealed that electric vehicles produced in India will also be equipped with Indonesian batteries.

Chairman Jeong Ui-seon said about the event, “There were ups and downs during the five-year preparation period, but I am very happy that we have reached this point today thanks to the efforts of our internal research institute and production technology department, as well as the strong support of the Indonesian ambassador and the Indonesian government.” He added, “There is a chasm regarding electric vehicles, but I believe we can overcome it.”

The reasons for selecting Indonesia as a base for electric vehicles included its abundant mineral resources, the Indonesian government’s clear policies, and the high adaptability of young Indonesian consumers to new technologies.

He also shared his opinion on the high market share of Japanese cars in the local market and the offensive of low-priced electric vehicles from China. Chairman Chung said, “It will not be much different from the strategy that Hyundai Motor Group is taking around the world,” and added, “In the end, the decision is made by the consumer, so I think the best response strategy is to develop technology in terms of the best quality, performance, and cost.” Regarding the level of internalization of electric vehicle technology by Hyundai Motor Group, Chairman Chung assessed that it has secured all technologies related to core electric vehicle components such as batteries and motors, but that it is still heavily dependent on overseas resources and materials.

Kim Min-beom, Donga.com reporter [email protected]

2024-07-03 17:13:57