2024 World Leather Fair Lineapelle On-site Report

“Are these all made of leather?”

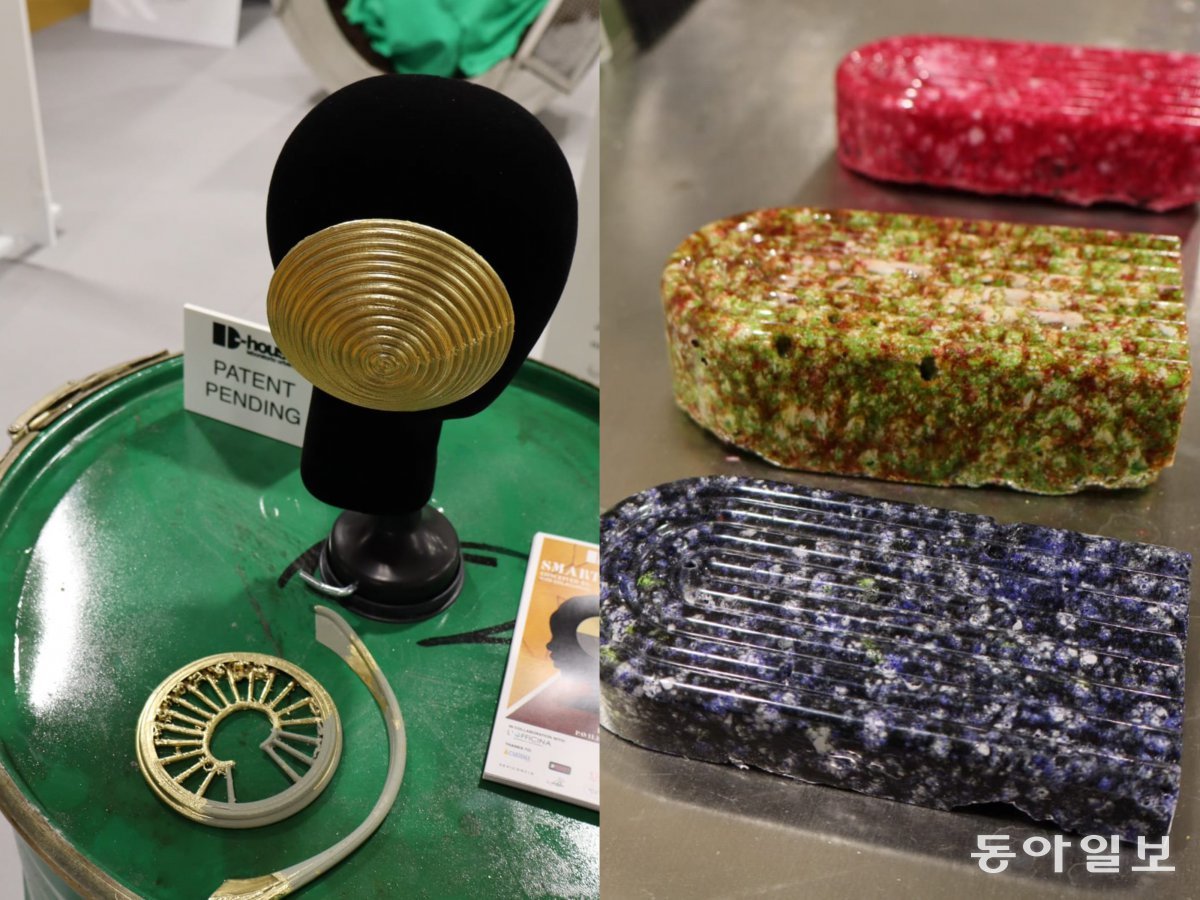

On the first day of the opening of the world’s largest leather fair, ‘Lineapelle’, held at the Fiera Milano Rho International Convention Center in Milan, Italy on the 17th (local time), the booth of the Milan-based fashion research and development (R&D) center D-House displayed products that were far from leather products, such as earrings and tiles.

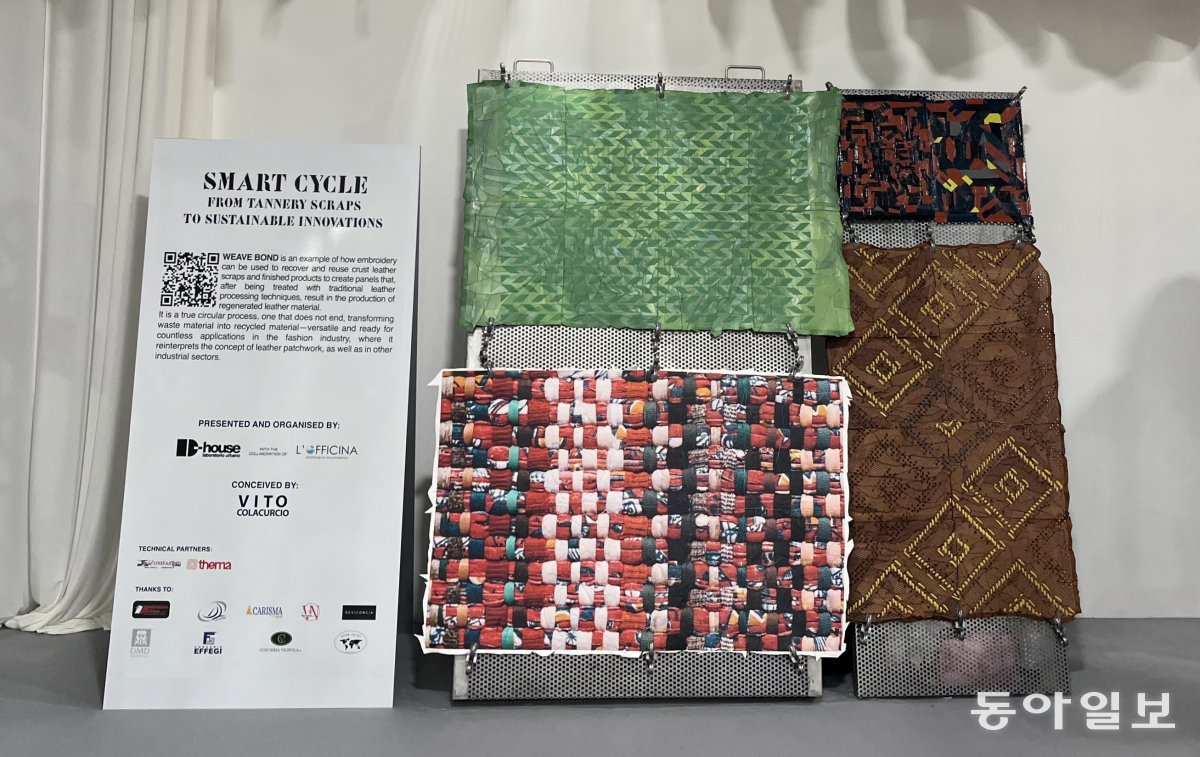

Only the scrap leather pieces covering the ceiling of the exhibition hall reminded me of the conveyor belt of a leather factory. Only the project name ‘SMART CYCLE – From Tannery By-product to Sustainable Innovation’ indicated that this exhibition was related to leather.

Lineapelle, which means ‘leather line’ in Italian, is a place where leather industry professionals from all over the world gather to discuss the latest trends and industry trends. It focuses on ‘leather’, a material used in various leather products such as shoes, clothing, furniture, and automobiles, and related parts and materials. Lineapelle, which began in Milan in 1981, is held twice a year in February and September for three days each time. This year’s Lineapelle was attended by 1,259 companies from 43 countries around the world, including Korea.

The theme of this year’s Lineapelle is ‘Innovation and Sustainability in the Leather Industry’. The leather industry faces the important task of overcoming the perception that it is old-fashioned while maintaining tradition, and achieving ‘sustainability’ in the leather production and processing process.

The ‘Smart Cycle’ project by Dihouse is part of the innovation of leather ‘technology’, and is a research project to reduce the environmental impact of leather and recycle byproducts generated during production and processing. The waste leather left after leather production is reprocessed into filament, a raw material for 3D printing, and is used to make earrings, colorful interior tiles, and embroidered carpets with various textures.

The leather powder generated during the surface finishing process was reused as a material that creates a natural cracking pattern in the leather, creating a bag fabric with a unique texture. In collaboration with a local Italian tannery, waste generated from actual leather production was utilized.

“All research is aimed at achieving sustainability in leather production. But that’s not all,” said Eva Monaccini, Dihouse Coordinator. “We are focusing on various leather byproducts and waste as new future resources and suggesting ways to utilize them according to their individual characteristics.” The technology to turn waste leather into filament and tile is currently under patent application.

The meeting, in which local consulting firm SPIN360 participated, discussed the impact of climate change on the leather industry. Federico Brunoli, CEO of SPIN360, emphasized in his opening remarks that “the fashion industry must respond to the climate crisis and environmental changes caused by humans.” Many environmental groups have raised issues related to environmental pollution and animal abuse caused by the leather industry, and this indicates that they intend to actively respond to these issues.

Shoe company New Balance also participated in this discussion. They shared their environmentally friendly strategies and actual implementation cases.

The Italian leather industry is also actively collaborating with international fashion schools. Six international fashion schools that collaborated with Lineapelle presented leather design innovations reinterpreted by the next generation of designers. In particular, the University of Campania Luigi Vanvitelli proposed a new leather design using generative artificial intelligence (AI). Novel attempts that are different from traditional leather, such as implementing the texture of leaves or fabrics dyed in pastel colors, were noticeable.

“AI is a tool that helps designers visualize creative products quickly,” said Roberto Liberti, an assistant professor at the University of Campania Luigi Vanvitelli, explaining that AI has shortened the entire process from design to production. The leather production process, which used to take two to three months, has been reduced to about two weeks thanks to AI.

Hongik University has also decided to participate in Lineapelle next February. Professor Lee Seung-ik’s team from Hongik University plans to present a fashion project that applies 3D printing to vegetable leather materials in collaboration with global 3D printing solution company Stratasys and Italian leather brand Dani. A space design project for autonomous vehicles, a collaboration between Professor Lee Kang-hyun’s team and textile manufacturer Kolon Glotech, will also be introduced.

Fulvia Bacchi, CEO of Lineapelle, emphasized to the Dong-A Ilbo, “Leather is difficult to handle and expensive, so it is difficult for young designers to access it. Lineapelle is supporting young designers to create creative works using leather and introduce them to the market.” He added, “We want to actively cooperate with young Korean designers and fashion schools in Korea.”

Milan = Reporter Kim Yun-jin [email protected]

-

- great

- 0dog

-

- I’m sad

- 0dog

-

- I’m angry

- 0dog

-

- I recommend it

- dog

Hot news right now

2024-09-19 15:15:37