Nanosystems prevents industrial disasters with lidar sensors that increase awareness

Starting a business in anticipation of expansion of the LiDAR ecosystem

7 years of research in parallel with custom production… Development of a sensor that recognizes both near and medium distances

Overcoming the mid-term abandonment crisis by ensuring demand… Combined with AI, contributes to minimizing industrial accidents

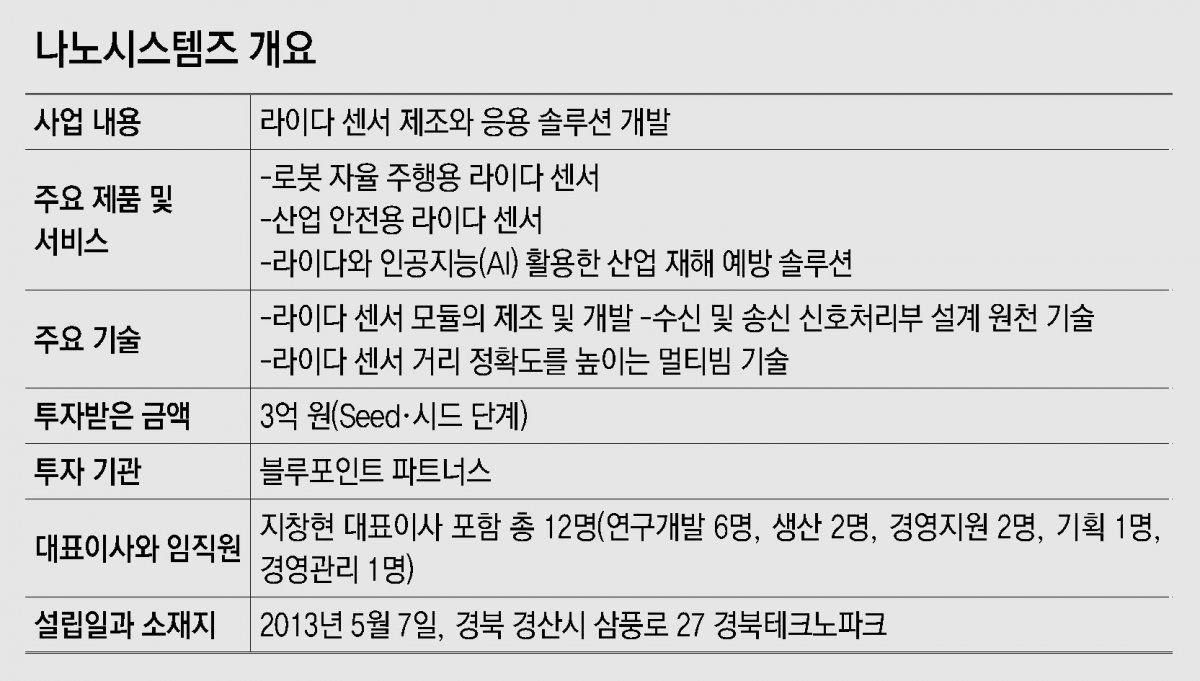

The road to starting a business is a long and difficult one. Lack of funds and manpower cleverly overlap to harass entrepreneurs. You can endure it only if you have your own goals and vision that seem within reach. This was the process of founding Nanosystems, which domestically produced lidar sensors for industrial safety.

Nanosystems, located in Gyeongbuk Techno Park, Gyeongsan-si, Gyeongsangbuk-do, developed a LiDAR sensor in 2020. The LiDAR sensor recognizes the surroundings by shooting a laser at a wavelength near infrared. It is widely used in autonomous vehicles and is widely known.

Lidar sensors are like the eyes of automation systems, so they are used in many places. It is attached to railroad safety doors (screen doors) in railroad and subway stations, and is also used in factories to dangerous places during the manufacturing process or to mobile robots that move goods. Nanosystems developed LiDAR sensors for mobile robots and industrial safety, not for autonomous vehicles.

Nanosystems expects sales this year to exceed 5 billion won. Operating profit is expected to be 300 million to 400 million won. Under these circumstances, we received our first investment this year, 11 years after our start-up. This is a different move from other startups that receive investment as soon as they are founded.

CEO Ji Chang-hyun (50), who met at the Nanosystems office in Gyeongbuk Techno Park on the 24th, said, “We started the business in 2013 and it took 7 years to develop the product. “Now that the product has started to be recognized in the market, I want to receive investment, promote the company, and do more.”

● Replacement of foreign sensors for railway platform safety doors

Among Nanosystems’ LiDAR sensors, the most sales-generating item is the LiDAR sensor used in railway platform safety doors. If a person is detected between the train entrance door and the safety door, the safety door is opened to prevent an accident that could result in injury to the person. Initially, many foreign sensors were installed, but now Nanosystems’ products are widely used, especially on national railway sections.

CEO Ji said, “2D (two-dimensional) foreign sensors are originally used in manufacturing plants and only recognize a very thin plane, whereas our product can recognize not only the plane but also the space of tens of centimeters between the train and the screen door, and can recognize snow and rain. , High-power electromagnetic wave immunity is also excellent.”

Nanosystems’ LiDAR sensor is in the form of a three-dimensional (3D) flash. Like a camera flash, a laser is fired over a large area at once to identify a specific location at once. With a viewing angle of approximately 110 degrees on the front, top, bottom, and left and right sides of the sensor, it recognizes up to a distance of about 10 meters at once. It detects human shapes as if taking a photo.

LiDAR sensors face increasing technical difficulties in recognizing from a distance. For autonomous vehicles, it recognizes people or objects at a distance of about 100 meters. CEO Ji said, “The companies developing sensors for autonomous vehicles have received trillions of investments to develop the technology,” adding, “I am confident that there will be many applications for use not only in autonomous vehicles but also in the industrial safety field, and I am confident that there will be many applications for short-range (within 10m) and medium-distance use.” “We focused on localizing lidar sensors for (within 30m),” he said.

Of course, Nanosystems is not the only company that makes LiDAR sensors. CEO Ji said, “We developed a multi-modulation frequency algorithm to reduce the error to within ±1% at a distance of less than 30m, and the difference is that we implemented short- and mid-range recognition in a single product.”

By applying these technologies, Nanosystems is developing and supplying outdoor delivery robots, indoor mobile robots for logistics, and unmanned golf cart sensors in addition to railway safety gates. There are also products that monitor abnormal body temperature by combining a LiDAR sensor and a thermal imaging sensor.

● Surviving through delivery of custom-made products and national projects

CEO Ji majored in computer engineering in college and worked in technical sales selling computer solutions at a mid-sized company. He said, “While working in sales, I really felt that it is not easy to sign a contract if you do not have a unique product. While conducting market research to select items with high future growth potential, a professor at the university who was providing technical advice told me that when autonomous vehicles come out, Lidar “After hearing that a sensor ecosystem would be created, after much thought, I decided to focus on LiDAR sensors and started a business,” he said.

From the beginning, he aimed to develop short- and mid-range LiDAR sensors that are easier to access than autonomous vehicle LiDAR sensors. During my sales activities, I heard through the network that the relevant organizations wanted to use domestically produced LiDAR sensors, such as those used in railway safety doors, but had no choice but to use foreign products because there was no place to manufacture them.

CEO Ji said, “I saw places where there seemed to be clear demand, such as for industrial safety or mobile robots,” and added, “Since I don’t have the technology myself, I started by looking into the market demand and developing related technology.” The capital was about 150 million won, including funds collected while working at the company.

To develop technology, we hired graduate students who majored in related fields and paid graduate school tuition so they could work at the company at the same time. CEO Ji said, “We did our best to cultivate research personnel. “I was confident in selling the product, so I had a great desire to make the sensor properly.” Together with graduate students, I carried out external research projects that were worth doing even if they were small in scale. By building up this kind of performance little by little, I was able to take on a fairly large national research project. We devoted 7 years to research using LiDAR technology while simultaneously providing services needed by companies in the Gyeongbuk region.

He recalled, “I thought about quitting around the 3rd or 5th year of starting the business as capital ran out and product development took longer than expected, but the market demand seemed clear and I didn’t give up because I thought the technology I had developed was a waste.” Nanosystems also partnered with external organizations such as the Korea Electronics Technology Institute and Yeungnam University to jointly develop technology. While developing the LiDAR sensor, we registered six domestic patents, one international patent, and trademark rights.

He tried to get investment in the early days of starting his business, but was not successful. CEO Ji said, “In the mid-2010s, we failed to attract investment because too much attention was focused only on autonomous vehicle LiDAR sensors,” and added, “Thanks to the technological capabilities we built up little by little, we received over 1 billion won in loans through technology news, etc. and have held on until now.” “He said.

● “Combining artificial intelligence (AI) will increase manufacturing process safety.”

![“We will do our best to localize lidar sensors for industrial safety by obtaining a loan exceeding 1 billion won.”[허진석의 톡톡 스타트업] “We will do our best to localize lidar sensors for industrial safety by obtaining a loan exceeding 1 billion won.”[허진석의 톡톡 스타트업]](https://dimg.donga.com/wps/NEWS/IMAGE/2024/09/28/130120693.1.jpg)

Nanosystems is currently supplying sensors used in mobile robots at manufacturing plants of famous large corporations, and sales are increasing by supplying products to domestic collaborative robot development companies.

CEO Ji has also begun to advance into the field of improving industrial safety by processing information about specific spaces recognized by LiDAR sensors with artificial intelligence (AI). He said, “Due to manufacturing practices, there are cases where workers approach the machine without stopping the automated machine. By installing a LiDAR sensor in such a place, it is possible to accurately recognize only the person and bring the machine to an emergency stop,” adding, “Safety without harming the efficiency of the factory.” “We have begun to provide solutions that maximize .” We are also planning to develop new solutions in partnership with industrial safety robot companies.

The goal is to become a company that provides LiDAR solutions for hazards and disasters both indoors and outdoors by increasing the detection distance and building AI technology for risk recognition behavior.

2024-09-28 17:12:28