How will our lives adapt to global warming? Scientists at the University of massachusetts, based in Amherst (United States), have imagined, during the period of confinement, a process to transform ordinary clothes “passive personal cooling tools”they write in the diary American Chemical Society from 18 October 2024.

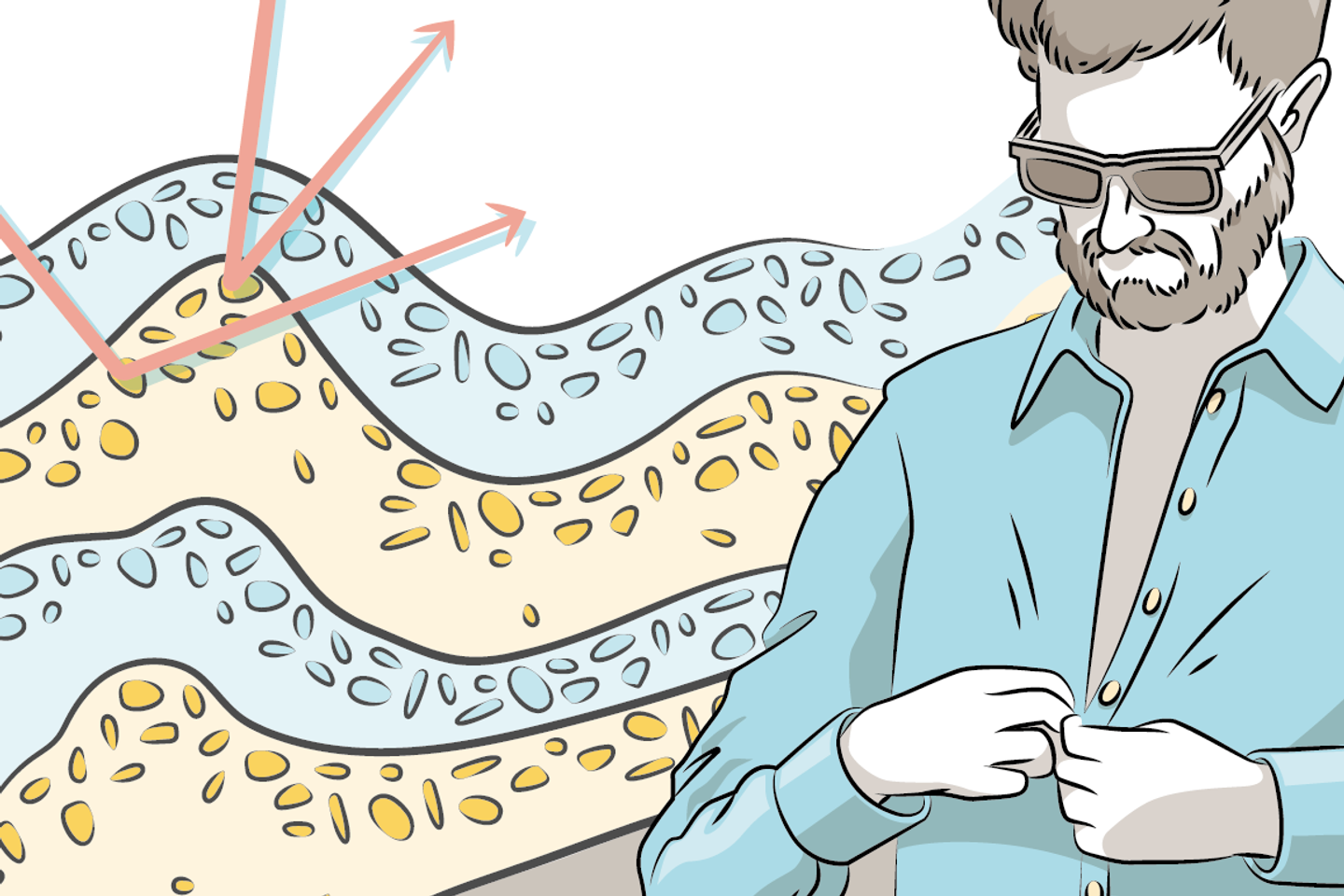

They coated the tissues with nanoparticles of calcium carbonate and barium sulfate, derived respectively from crushed oyster shells and barite, a natural mineral used as a contrast agent for gastric X-rays. After multiple tests, two alternating very thin layers of each material allowed thermal results to be achieved” which surprised us ourselves”recognizes scientist Trisha Andrew, professor of chemistry and chemical engineering, who led the research. The coated garment allowed the person wearing it to feel 3.4°C cooler on average than those wearing traditional clothing. The scientists are in talks with several manufacturers to develop the resulting prototype.

“In some parts of the globe,living will be increasingly intricate from a biological point of view,explains Trisha Andrew. When a person steps out into the sunlight, their body and clothing absorb the light, which is converted into heat by a multitude of molecular mechanisms. » Hence the design of this material which repels the sun’s heat while letting the skin breathe. “It is not an active cooling mechanism but a passive radiative process”precise.

Good reception from the textile industry

For researcher Tricia Carmichael, from the University of Windsor (ontario, Canada), “This research constitutes significant progress, because it allows common clothing to be transformed in a practical and simple way, even giving them a second life”. The biochemistry professor, who is currently working on theincorporation of electronic compounds in the textile sector, highlights the advantages of the coating process developed by the team. “Chemical vapor deposition [CVD] and subsequent soaking in aqueous solutions are ideal because they coat the individual fibers of the fabric while maintaining the overall structure of the fabric, including its texture and softnessexplains. This choice also allows us to avoid the use of organic solvents, which are harmful to industry and the surroundings. »